AMABOX offers a wide range of modules to revolutionize the handling of ingredients. This range of modules make countless configurations of the AMABOX System possible. These configurations vary from small ingredient storage options to 100% automating hundreds of different ingredients.

The AMABOX System can grow with your factory

The AMABOX System is scalable and modular. This means that it can be applied in any pellet and granulates handling factory, and as your production grows, the AMABOX System can grow with you.

This flexibility regards the number of ingredients, total storage capacity, dosing capacity & number of mixing lines. The following examples show some of the applications of the AMABOX System.

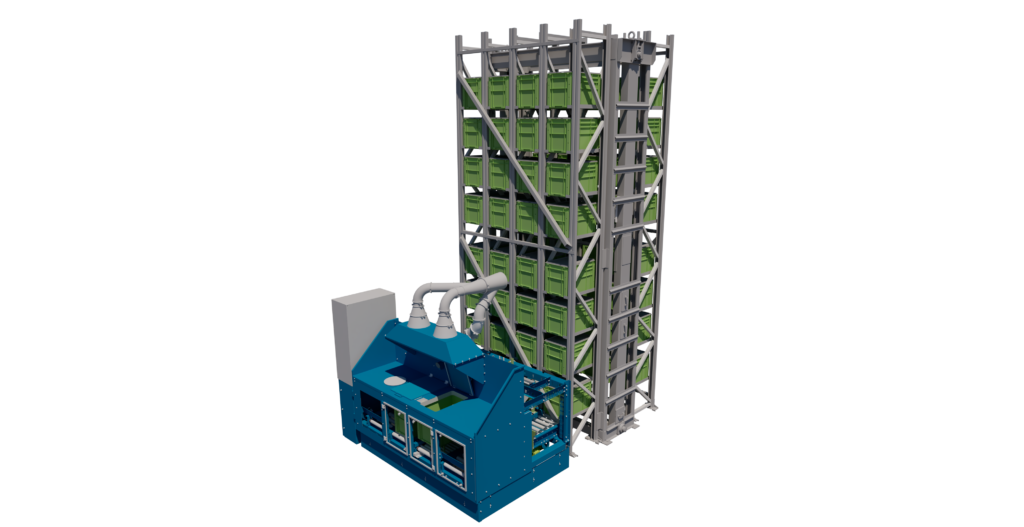

Ingredient storage and assisted dosing & weighing

This implementation of the AMABOX System creates solid storage options for small ingredients (up to 120 different ingredients) and assisted dosing & weighing with the SpeedBuffer and ManDoser.

- to 60 different ingredients

- 4+ tonnes of small ingredient stock

- 20 – 50 dosings per hour

This makes for full tracking & traceability, reduced chance of error and contaminations.

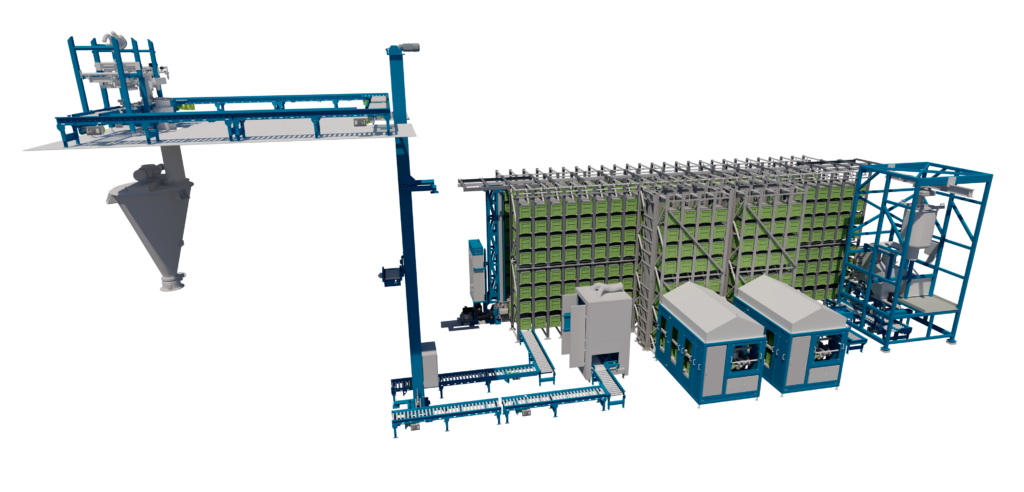

fully automated storing, Dosing & weighing and tipping

In a configuration like this one, the AMABOX System has room for small ingredients (up to 120 different ingredients) that are 100% automatically dosed & weighed with the SpeedBuffer and BoxDoser. These ingredients are then automatically tipped in the blending line with the BoxTipper. Filling can be done with one of our filling options.

- to 60 different ingredients

- 4+ tonnes of small ingredient stock

- 60 – 90 dosings per hour

This makes for automated ingredient dosing, weighing and tipping. Full tracking & traceability, reduced chance of error, cross-contaminations and vastly improved working conditions for operators.

100% automated ingredient handling, increased flexibility and efficiency

Automating your full production process is now possible. With this configuration of the AMABOX System, all manual dosing & weighing, storing, and hand tipping belongs to the past. With the BoxFilling Combi, boxes are filled from bags and big bags. the BoxCleaner keeps boxes clean.

- to 300 different ingredients

- 20+ tonnes of ingredient stock

- 120 – 180 dosings per hour

It has a huge impact on labour costs, provides high accuracy, and low cross contamination. The system is fully scalable and grows with you and your factory.

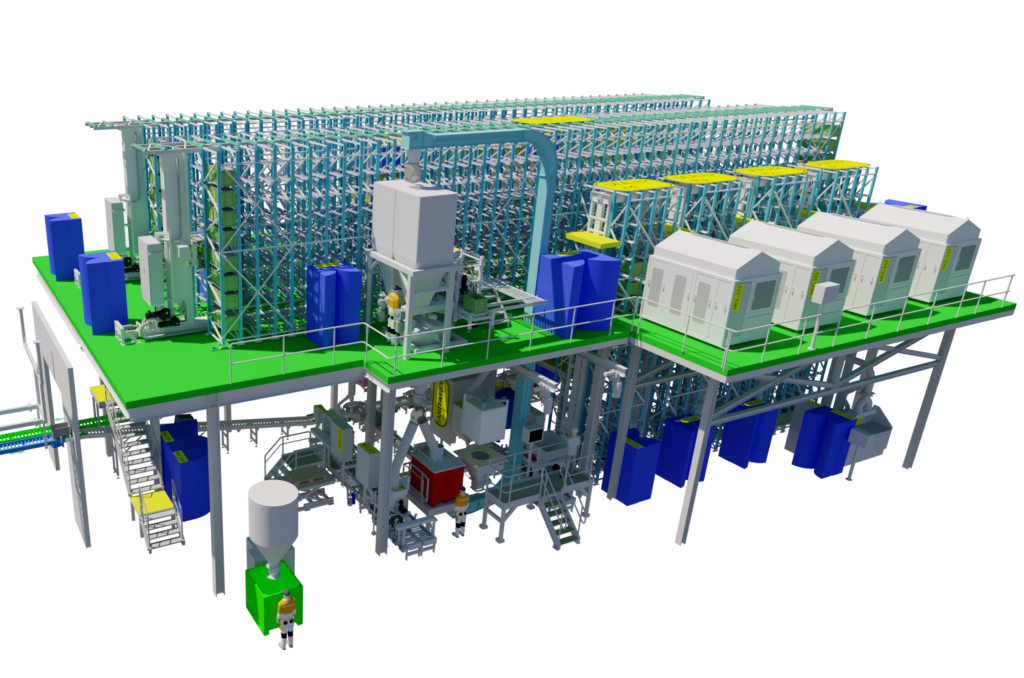

Full automation of all handling

This maxed-out version of our system can automate ingredient handling across your large plant. AMABOX is the solution for the manual additions of hundreds of ingredients, that are added in small and large amounts. Even mixing, cleaning and moving ingredients over hundreds of meters of transport is no issue.

- 500+ different ingredients

- 120+ tonnes of ingredient stock

- 360+ dosings per hour

The system increases overall efficiency and flexibility of the process and lowers error risks. The automation enables tracking & tracing and reduces dust in the factory.

more information?

or follow us on LinkedIn