Our solutions to eliminate manual ingredient handling are the first of its kind. The AMABOX System is a revolutionary way of handling ingredients in your factory.

The system 100% eliminates manual dosing & weighing of ingredients. This will drastically improve working conditions, quality and plant efficiency.

Dosing without manual weighing and tipping – AMABOX shows it’s possible

Harm Klein – Molenaar Magazine March 2022

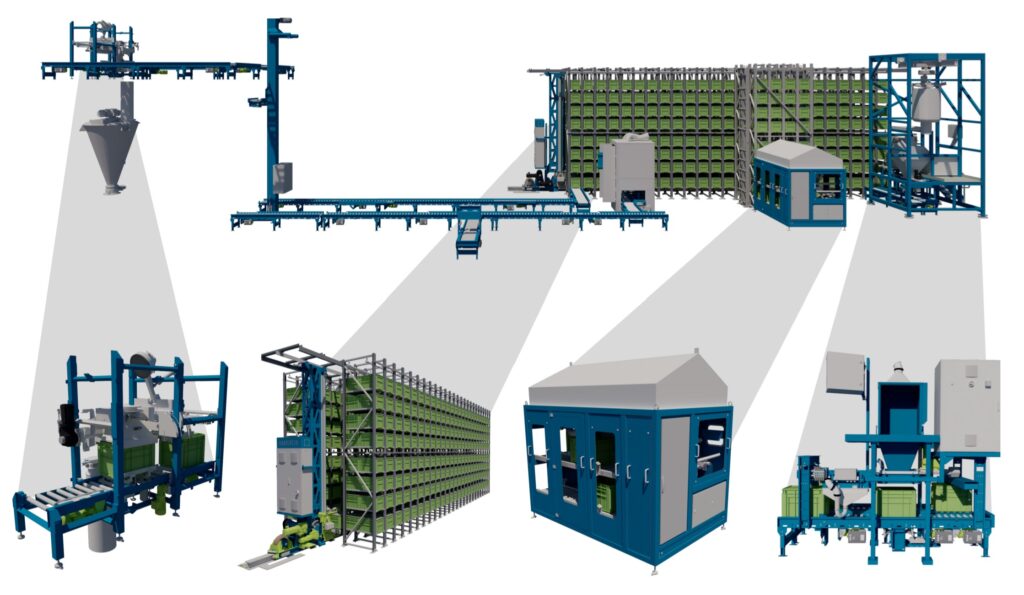

The system 100% eliminates manual ingredient handling, including dosing, weighing, tipping & storing. All ingredients are stored in boxes, that are automatically transported, filled and cleaned. This will drastically improve working conditions, quality and plant efficiency. The AMABOX System consists of different modules that can be configured to the customers’ wish.

The range of modules make countless configurations of the AMABOX System possible. These configurations vary from small ingredient storage options to 100% automation of hundreds of different ingredients.

There is flexibility in number of ingredients, total storage capacity, dosing capacity & number of mixing lines.

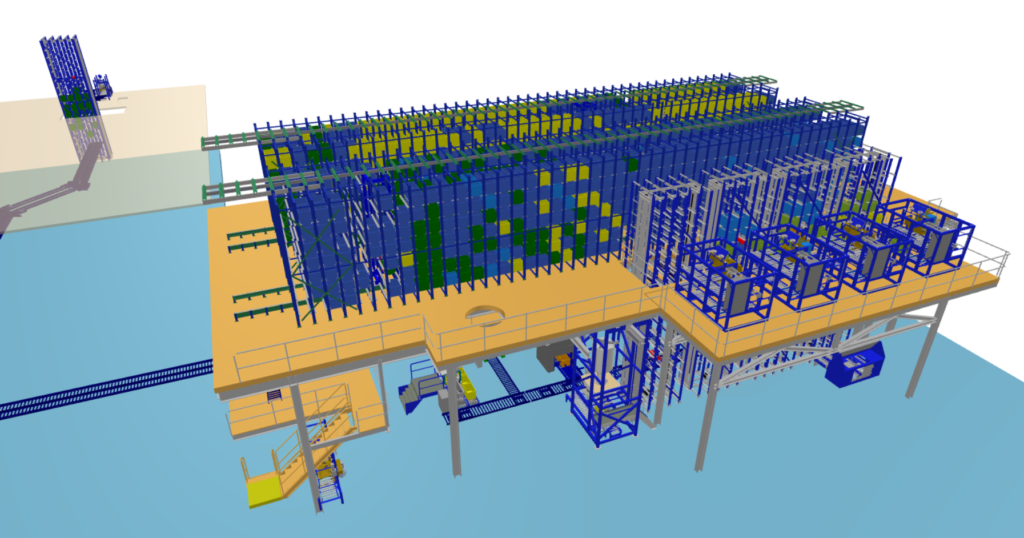

With 3D scanning, simulation, digital twinning and machine learning solutions, we make sure that promised production can be realized.

AMABOX digital twin simulates production and ensures integration with the rest of the factory. Machine learning algorithms increase accuracy and speed of dosing by learning characteristics of ingredients.

more information?

or follow us on LinkedIn